Ningbo Jiuyi Precision Mould Co.,Ltd.

We specialize in serving customers in the hardware mold and stamping industries of the fastener industry!

New Product

-

PUNCH SERIES

Cross-shaped Titanium-coated M2 M42 Punch for Stainless Steel Thread Heading Machines,Phillips header punch

Rated 0 out of 5Read more -

MOULD SERIES

Independent Guide Column Guide Sleeve Mold Accessories Such As MYZP/MYAP/MYKP, Etc. with Seat Ball Components

Rated 0 out of 5Read more -

MOULD SERIES

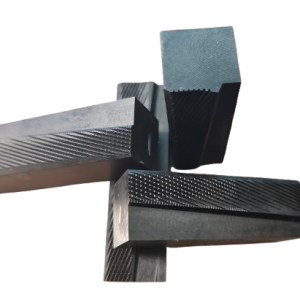

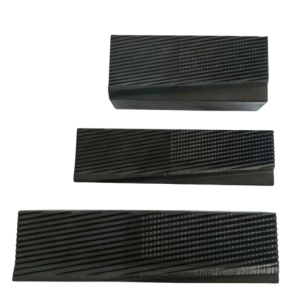

High Wear-resistant Thread Rolling Wheel Dies, Net Pattern and Straight Line Rolling Machine Dies

Rated 0 out of 5Read more -

-

-

-

MOULD SERIES

Cold heading screw die, hard alloy, tungsten steel material main die, straight hole die.

Rated 0 out of 5Read more -

-

-

-

-

-

-

-

-

-

-

About Us

COMPANY INTRODUCTION

Ningbo Jiuyi Precision Mould Co., Ltd. was founded in June 22,2020, the company is located in Yinzhou District, Ningbo City, Zhejiang Province, Jiangshan Town, Maoshan Industrial Zone, Longteng Road, the plant covers an area of about 1,000 square meters, the staffof 20-30 people.

The company focuses on the production and customization of mold accessories, such as shaping punch bar, position- ing punch bar, lead hole punch bar, molding punch bar, stretching punch bar, slotting punch bar, punching punch bar, etc.; according to the shape can be divided into: round punch bar, four-corner punch bar, five-corner punch bar, six-corner punch bar, eight-corner punch bar, twelve-cor- ner punch bar, plum blossom punch bar, mother and child punch bar, star punch bar, and other shaped punch bar.

Our Products

PRODUCT MATERIALS

The material selection of the punch bar is based on high-speed steel, commonly used materials are Japan’s SKH9,SKH55, SKH59, U.S. M2, M35, M42; the main feature of the material is that high-speed punching upsetting the material to maintain a good red hardness, but also excel- lent wear resistance, and can ensure a certain degree of toughness; there are also some of the powder high-speed steel materials, commonly used for ASP23, ASP30, ASP60, the performance of the material is worried about the high-speed steel, but its price is high and the stock is complete, the scope of use is relatively small, ASP60, the performance of the material is better than high-speed steel, but its price is high, and the inventory is not complete, the scope of use is relatively small. Tungsten steel punching rod is a few enterprises in recent years can produce new products, mainly using cemented carbide production, the toughness of the material require- ments are very high, the production of the technical threshold is also relatively high, the production cost is also very high, commonly used in stainless steel cold upsetting

industry and heavy deep-drawing field. Surface treatment of punching rodWith the improvement of product quality in China, more and more production enterprises have very high expectation to improve the service life of punch- ing rod. Titanium plating on the surface of the bar is a very good choice; the advantage is that the size of the workpiece after titanium plating is well controlled, the thickness is generally 2-3UM, and the deformation of the bar is also very small, which is very suitable for the surface treatment of the bar. After titanium plating, the surface friction coefficient of the punching rod is reduced and the surface hardness is increased, which makes the wear resistance of the punching rod increase greatly, thus the life span of the punch- ing rod is also greatly prolonged. The types of titanium layer are commonly used as TIN, TICN, TIALN, ALCRN,etc.